Choosing gas pipe wrench

Despite the name, gas wrench serves more than just gas pipes. It is a universal tool for construction, installation and plumbing works, as well as repairing a wide scope of equipment.

Gas wrenches are used to fix and rotate circular parts, therefore they are often referred to as pipe wrenches. Their main feature is rigid fixation of the part using sharpened prongs on the jaws, which allows processing parts without clear edges. The clamping force is set with a handle. Nevertheless, gas wrenches are applied when working not only with pipes, but also with hex nuts and bolts.

History of gas wrench

Gas wrench is a type of adjustable wrench, which is quite an ancient tool, and the period of its active improvement and implementation of the various modifications, depending on the performance type, refers to the 19th century, when adjustable, ratchet, pipe, self-tightening and other wrench types began to appear in locksmith toolbox.

Tool manufacturers competed to invent the perfect design, made and even bought each other's patents. And some of these inventions are still referenced. For example, the RIDGID pipe wrench, invented in 1923, not only flaunts the company logo, meanwhile there is a number of tools acquired by craftsmen almost 100 years ago are transmitted from one generation to another and still keep working. They are also ensured with the Ridgid's lifetime warranty.

Gas wrench sizes

Pipe wrenches differ in number.

As per GOST, there are only 5 gas wrench sizes. The number indicates the wrench length and the range of suitable pipe diameters ranged from 10 mm to 120 mm.

Gas wrenches of sizes 1 to 3 are applicable for household works. Wrenches numbered 4 and 5 are professionally used.

Gas wrench size table

| Pipe wrench number | Wrench length, mm | Weight up to, kg | Pipe diameter in mm |

| 0 | 200 | 0,4 | 5–20 |

| 1 | 300 | 0,8 | 10–35 |

| 2 | 400 | 1,3 | 20–50 |

| 3 | 500 | 1,9 | 20–65 |

| 4 | 650 | 3,5 | 25-90 |

| 5 | 750 | 5,8 | 32 -120 |

Gas wrench 1 (KTR No. 1) has a length of 300 mm and suitable for working with pipes or parts with diameter of 10 to 36 mm. Using it, home artisans can also tighten and loosen all sorts of threaded connections.Gas wrenches 2 (KTR No, 2) and 3 (KTR No. 3) are often called a plumbing pair. They are indispensable for dealing with heating and water supply pipes in apartments, houses and offices. The length of gas wrench No 2 is 400 mm, it is intended to work with pipes with diameter of 20-50 mm. Wrench number 3 is 500 mm long and ensures capacity of clamping pipes with diameter of 20 to 63 mm.

Gas wrenches 4 and 5 are serious tools for heavy duty and expert use. They are made from carbon, chrome vanadium or tool steel, and are also subjected to special additional treatment to increase their toughness.

Wrench KTR No. 4 is 630 mm long and applicable for pipes with diameter of 25-90 mm. As the wrench is used for installation and dismantling of gas equipment, stoves, water heaters, heating boilers, it is equipped with particularly shaped wear-resistant prongs for reliable clamping.

Gas wrench 5 can cope with pipes of diameter ranged from 32 to 120 mm. Its length is 700 mm, and its substantial weight requires skill, which is possible only with the prolonged expert training.

All gas switches are of the same design and differ in the shape of jaws, straight and inclined or S-shaped. Straight or inclined jaws are generally used. S-shaped jaws fix the pipe at three points, this reduces the risk of its slipping during operation and supplies the stronger grip on the round profile. Therefore, they are often applied for the complex connections that are difficult to work with the other wrench types.

The 90 or 45 degree tilt of pipe wrench jaws allows access to a pipe in all working conditions.

In Russia, the pipe wrench marking is adopted as per GOST 18981-73. To make the search of the suitable wrench with markings from foreign manufacturers more convenient, there are special matching tables with the pipe wrench sizes.

Matching Table for the Ridgid pipe wrenches

| Pipe wrench photo | Model | Wrench name | Pipe diameter in inches | Wrench weight, kg |

|

Ridgid 1140 | Gas pipe wrench No. 0 | 3/4 | 0,4 |

|

Ridgid 1141 | Gas pipe wrench No. 1 | 1 | 0,7 |

|

Ridgid 1142 | Gas pipe wrench No. 2 | 1 1/2 | 1,3 |

|

Ridgid 1143 | Gas pipe wrench No. 3 | 2 1/2 | 2,9 |

|

Ridgid 1144 | Gas pipe wrench No. 4 | 3 1/2 | 5,3 |

|

Ridgid 45° 1/2" | Gas pipe wrench No. 0, jaw angle 45 ° | 1/2 | 0,4 |

|

Ridgid 45° 1" | Gas pipe wrench No. 1, jaw angle 45 ° | 1 | 0,9 |

|

Ridgid 45° 1 1/2" | Gas pipe wrench No. 2, jaw angle 45 ° | 1 1/2 | 1,4 |

|

Ridgid 45° 2" | Gas pipe wrench No. 3, jaw angle 45 ° | 2 | 2,7 |

|

Ridgid 45° 3" | Gas pipe wrench No. 4, jaw angle 45 ° | 3 | 3,5 |

|

Ridgid 90° 1" | Lever pipe wrench No. 1, jaw angle 90 ° | 1 | 0,4 |

|

Ridgid 90° 1 1/2" | Lever pipe wrench No. 2, jaw angle 90 ° | 1 1/2 | 0,9 |

|

Ridgid 90° 2" | Lever pipe wrench No. 3, jaw angle 90 ° | 2 | 1,4 |

|

Ridgid 90° 3" | Lever pipe wrench No. 4, jaw angle 90 ° | 3 | 2,7 |

|

Ridgid 90° 4" | Lever pipe wrench No. 3, jaw angle 90 ° | 4 | 3,5 |

|

Ridgid S 1/2" | Lever pipe wrench No. 0 type "S" | 1/2 | 0,4 |

|

Ridgid S 1" | Lever pipe wrench No. 1, type "S" | 1 | 0,9 |

|

Ridgid S 1 1/2" | Lever angular pipe wrench No. 2, type "S" | 1 1/2 | 1,4 |

|

Ridgid S 2" | Lever angular pipe wrench No. 3, type "S" | 2 | 2,6 |

|

Ridgid S 3" | Lever angular pipe wrench No. 4, type "S" | 3 | 4,2 |

Gas wrench varieties

Jaws and prongs

Classic gas wrench varieties are equipped with straight jaws at 45 or 90 degrees to the handles.

To deal with pipes of a complex shape, there are special wrenches with S-shaped jaws, which allow fixing an object at 3 points.

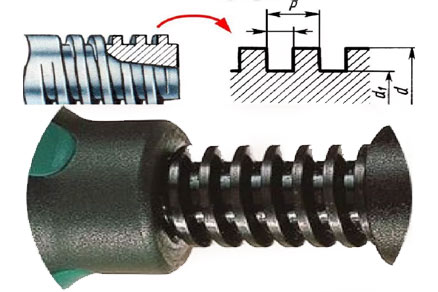

To ensure a secure grip, the rifling of jaw prongs is made inclined against the direction of rotation.

If the tool has defective prongs or jaws, it can damage the part. When abrasion of the prong tops reaches 0.4 mm, the lever gas wrench must be written off, and the jaws must be changed to the new ones in models with replaceable jaws.

Lever gas wrenches

Lever gas wrench consists of two expandable handles connected by lever mechanism. The upper handle is powered and fixed, and the lower handle is movable and adjusted for grip. Lever wrench handles enable to increase the clamping force by clenching them.

The patent for this adjustable wrench modification was issued in 1892 to the Swede Johan Peter Yuhansson (Johansson). Since then, they are called Swedish-type gas wrenches or "Swedes" worldwide.

| Ridgid 1140 | RIDGID 90˚-1 1/2" |

|

|

| Price 2 521 rub. | Price 3 061 rub. |

Gas pipe wrenches of the American type

They belong to a category of the adjustable ones. The extension adjustment is carried out using the adjusting nut. The cast iron and I-section main handle is a continued part of the body. It can be of the same width or with a limiting overhang for the better grip and a hole for suspension.

The gas pipe wrenches, unlike the lever ones, are equipped with the replaceable clamping jaws, this allows them to be renewed when the prongs are worn out or fail.

Chain Gas Wrenches

Chain wrenches are designed for working with large diameter pipes and in limited spaces. Therefore, they are particularly fitted with a chain mechanism, which grips the pipe along its entire diameter, and then locks it with a clamp.

Owing to the extended arm, chain pipe wrench enables to fulfil hard and high-loaded works in limited spaces with less effort.

Chain gas wrenches belong to the professional tool range. They are made of high-strength steel, with extra aluminum applied to reduce the wrench weight.

| Chain Gas Wrenches Ridgid C-12 | Ridgid 3229 | Chain Gas Wrenches Ridgid 3215 |

|

|

|

| Price 4 798 rub. | Price 23 708 rub. | Price 202 507 rub. |

Belt wrenches

Belt gas wrenches are applied for installation and repair of chrome, nickel, plastic and other types of pipes that are sensitive to external mechanical impacts. The belt wrench construction is similar to the chain one, but a special strong belt or tape is provided for gripping a pipe, to exclude the pipe damage and deformation. The belt is covered with a special polyurethane-based layer for a firm grip on pipes with slippery surfaces and to extend the service life. The possibility of changing the belt allows extending the wrench service life.

| Strap Wrenches №2 | Strap Wrenches Ridgid | Strap Wrench for Plastic Ridgid 2P |

|

|

|

| Price 3 374 rub. | Price 2 956 rub. | Price 3 658 rub. |

Choosing gas wrench

When choosing wrench, special attention should be paid to the quality of its material, the manufacturer reputation, as well as to assess the volume and complexity of the performed work.

The high tool quality is a guarantee of the safety of pipes and other parts to be dealt with, and also the master’s safety.

Quality tool is noticeable with a smooth, well-processed surface, having no pits, burrs or cracks. The prongs of the working edges must be sharp. As a rule, the manufacturer's logo is clearly visible on the tool, along with the indicated information, which material the tool is made of: CHROME STEEL ALLOY, CHROME VANADIUM, CHROME MOLYBDENUM, etc.

- Комментарии